When buying shawls in bulk—whether for retail, corporate gifting, or special events—quality is everything. A single flaw in weaving, dyeing, or stitching can tarnish your brand’s image. That’s why choosing a manufacturer with a proven track record in Shawl’s Manufacturer Quality Control is essential.

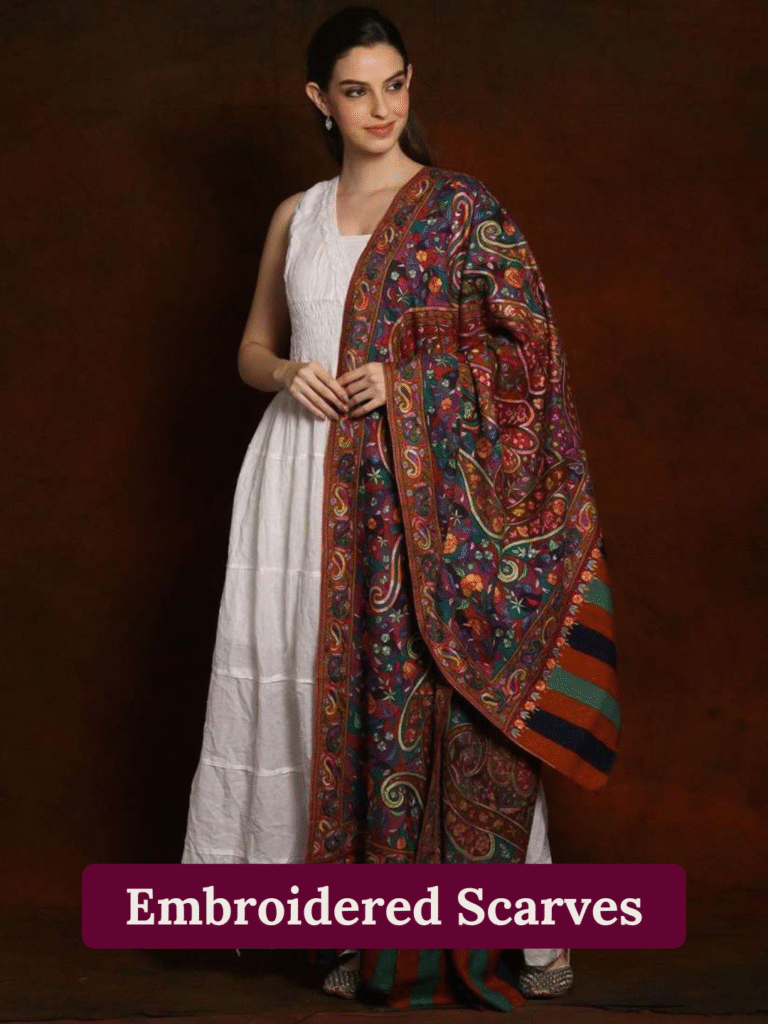

Savita Shawls, a leading name in India’s textile industry, has perfected the art and science of producing flawless Pashmina Shawls and Scarves, Cashmere Shawls, Silk Scarves, Wedding Shawls, and Fashion Scarves. But what exactly goes on behind the scenes to ensure each piece meets world-class standards? Let’s take you through the journey.

1. The Foundation: Sourcing Premium Raw Materials

Every quality product begins with quality raw materials. At Savita Shawls, the quality control process starts with selecting only the finest fibers:

- Cashmere from trusted suppliers in the Himalayan region.

- Pure silk threads for lustrous Silk Scarves.

- Authentic Pashmina wool for Pashmina Shawls and Scarves.

These materials are carefully inspected for purity, softness, and durability before production begins.

2. Pre-Production Testing and Sampling

Before mass production, the manufacturer creates sample pieces for client approval. This stage is crucial for ensuring:

- Color Fastness – Fabrics are tested to ensure dyes won’t fade or bleed.

- Fabric Strength – Shawls are checked for weave consistency and tear resistance.

- Design Accuracy – Patterns, prints, and embroidery match the approved concept.

Savita Shawls sends these samples to clients within 7 days, allowing for any changes before the bulk order begins.

3. Skilled Weaving by Expert Artisans

India is known for its weaving heritage, and Savita Shawls keeps this tradition alive while blending it with modern technology. Quality control during weaving involves:

- Checking loom settings before every production run.

- Monitoring thread tension to prevent uneven patterns.

- Inspecting each piece after it comes off the loom.

This ensures Shawl’s Manufacturer Quality Control is maintained at every stage.

4. Dyeing and Printing with Precision

Colors make shawls visually appealing, but uneven dyeing can ruin a product. Savita Shawls uses:

- Eco-friendly dyes to reduce environmental impact.

- Digital printing for high-definition patterns.

- Batch testing to ensure color uniformity across all items.

From vibrant Fashion Scarves to elegant Wedding Shawls, color consistency is non-negotiable.

5. Meticulous Finishing Touches

Once weaving and dyeing are complete, each shawl goes through a finishing department for:

- Hand hemming to avoid loose threads.

- Embroidery inspection for symmetry and stitch quality.

- Steam pressing for a crisp, elegant finish.

This stage ensures Silk Scarves, Pashmina Shawls, and Cashmere Shawls have the perfect final look before packaging.

6. Final Quality Inspection Before Dispatch

Before a shipment leaves the warehouse, every shawl undergoes a final inspection process:

- Measurement Check – Ensuring the exact dimensions as per client requirements.

- Surface Examination – Looking for stains, snags, or irregular patterns.

- Weight & Fabric Test – Ensuring consistent quality across the batch.

Only after passing this stage are shawls packaged and shipped to clients worldwide.

7. Packaging and Global Shipping Standards

High-quality products deserve equally high-quality packaging. Savita Shawls uses:

- Moisture-proof wrapping to protect delicate fabrics.

- Reinforced boxes for long-distance shipping.

- International courier services like DHL, FedEx, and UPS for reliable delivery.

This attention to detail ensures customers receive their shawls in perfect condition, no matter where they are in the world.

8. Continuous Feedback and Improvement

Savita Shawls believes Shaw’s Manufacturer Quality Control is not a one-time process but a continuous cycle. After every delivery:

- Client feedback is collected.

- Production notes are updated.

- Any reported issues are resolved in future batches.

This ongoing commitment helps maintain strong, long-term relationships with retailers, wholesalers, and fashion designers.

Why This Process Matters for Your Business

For retailers and wholesalers, consistent quality means:

- Higher Customer Satisfaction – Fewer returns, more repeat buyers.

- Stronger Brand Reputation – Customers trust your products.

- Better Profit Margins – Premium products command higher prices.

Whether you’re sourcing Wedding Shawls for a bridal boutique or Fashion Scarves for a seasonal collection, working with a manufacturer that prioritizes quality control ensures your investment pays off.

Final Thoughts

The journey from raw fiber to a finished shawl involves countless steps, each demanding precision and care. Savita Shawls’ meticulous approach to Shaw’s Manufacturer Quality Control ensures every Pashmina Shawl, Cashmere Shawl, Silk Scarf, Wedding Shawl, and Fashion Scarf meets the highest standards.

For businesses looking to partner with a reliable, ethical, and skilled shawls manufacturer, Savita Shawls offers a blend of tradition, innovation, and uncompromising quality.