When it comes to drilling precise, deep holes in wood, soil, or even ice, few tools match the power and efficiency of the auger bit. Known for its spiral design and self-feeding tip, the auger bit has been a cornerstone in construction, carpentry, and home improvement for decades. Understanding the different types of auger bits, their builds, and practical applications is essential for selecting the right tool for the job—whether you’re framing a house or fencing a backyard.

What Is an Auger Bit?

An auger bit is a type of drill bit designed to bore deep, clean holes with minimal effort. Its helical screw blade pulls the bit into the material, reducing the need for excessive pressure. The key advantage of auger bits is their cutting efficiency—they remove material (chips or shavings) as they drill, keeping the hole clean and preventing overheating.

Auger bits come in various sizes and shapes, each designed for specific materials and use cases. While they’re most commonly associated with wood, auger bits are also engineered for soil, ice, and even masonry in specialized versions.

Anatomy of an Auger Bit

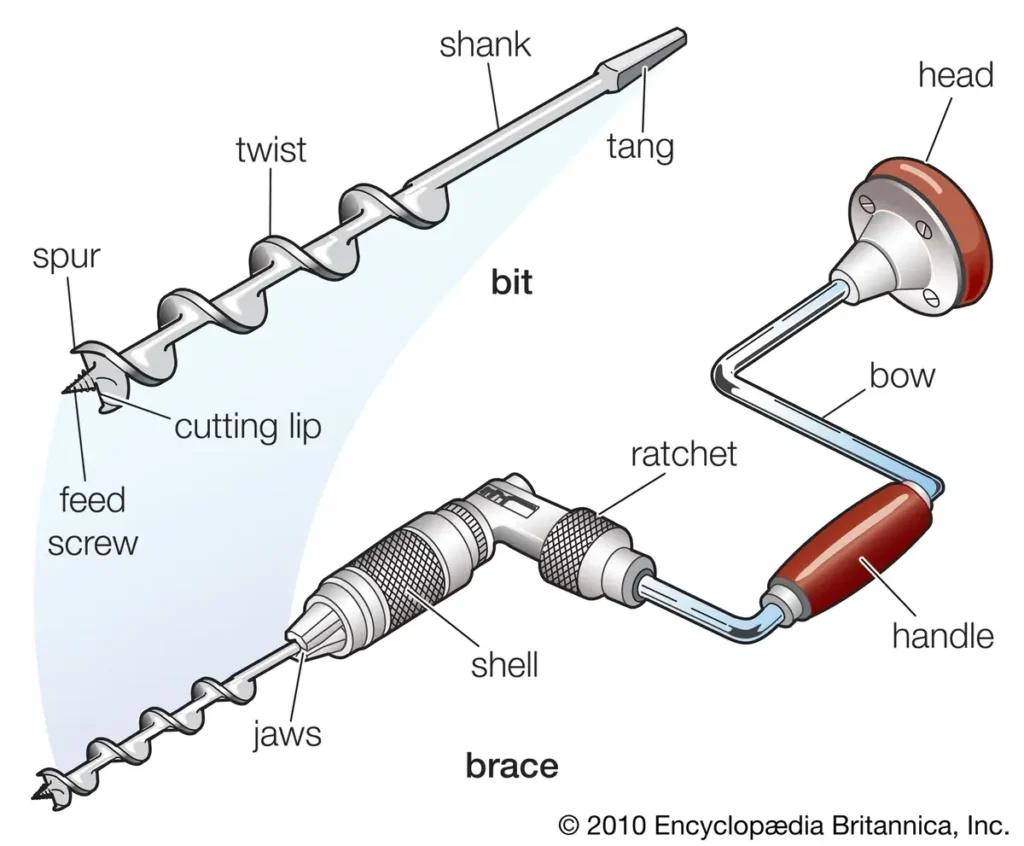

Understanding the build of an auger bit helps in choosing the right one for your application. The main components include:

Screw Tip (Feed Screw): This threaded point grips the material and pulls the bit forward with consistent pressure.

Spur or Cutting Edge: These sharpened edges score the outer circumference of the hole for a cleaner finish.

Flutes: The helical grooves along the shaft that remove chips or debris from the hole.

Shank: The end that fits into the drill or brace, typically hex or round depending on the tool.

High-quality auger bits are typically made from high-carbon steel or high-speed steel (HSS), offering strength, durability, and resistance to wear. Some premium models also feature titanium or carbide coatings to enhance performance and longevity, especially in tough materials.

Common Types of Auger Bits

Wood Auger Bits

The classic auger bit most DIYers and builders recognize. Designed for boring deep holes in soft or hardwoods, these bits are perfect for framing, timber construction, and installing large bolts or dowels.

Best for: Structural woodwork, decking, and cabinetry.

Pro Tip: Choose bits with precision-ground cutting edges for faster drilling and smoother holes.

Ship Auger Bits

Built for heavy-duty use, ship augers have a thicker body and a single flute for clearing large wood chips. They can cut through wood embedded with nails or screws without losing sharpness.

Best for: Framing, utility installation, and drilling through treated lumber.

Pro Tip: Ideal for electricians and plumbers running lines through joists or beams.

Earth Auger Bits

These large-scale augers attach to powerheads or handheld earth drills. Their wide spiral blades remove soil efficiently for digging post holes, planting trees, or setting fence posts.

Best for: Landscaping, fencing, and light construction.

Pro Tip: Select bits with replaceable cutting edges to extend lifespan and performance.

Ice Auger Bits

Designed specifically for ice fishing or drilling through frozen surfaces, ice augers have sharper cutting blades and wider spirals for ejecting ice shavings quickly.

Best for: Ice fishing, winter drilling applications.

Pro Tip: Keep the blades protected with covers—sharpness is key for clean cuts through dense ice.

Masonry Auger Bits

While less common, masonry augers combine the auger design with carbide-tipped edges for penetrating brick, stone, or concrete.

Best for: Anchoring, foundation drilling, and specialized construction tasks.

Choosing the Right Auger Bit

Selecting the right auger bit comes down to material, hole depth, and drill type.

For woodwork, choose a standard or ship auger depending on density.

For outdoor or ground applications, go with earth augers sized for your post or root diameter.

For ice or masonry, use purpose-built augers designed for those materials—standard wood bits won’t survive the stress.

Also, match the shank size to your drill’s chuck capacity. Larger augers often require powerful corded drills or auger-specific drivers for consistent torque.

Maintenance & Safety Tips

Keep edges sharp: Dull bits cause heat buildup and rough holes. Sharpen or replace when necessary.

Lubricate periodically: Especially for metal or dense wood applications.

Clear chips often: Prevent jamming by lifting the bit occasionally to remove debris.

Use proper speed: Lower speeds for deep holes or dense materials; higher speeds for shallow or soft materials.

Wear protection: Safety goggles and gloves are essential when using power augers.

Final Thoughts

Auger bits remain indispensable for anyone in construction, woodworking, or home improvement. Their ability to bore precise, deep holes quickly and cleanly makes them a must-have in every professional’s toolkit. Whether you’re installing a deck, setting fence posts, or wiring a new build, the right auger bit saves time, reduces strain, and delivers cleaner results.

Investing in quality auger bits—built with durable materials and precision engineering—ensures smoother work, longer tool life, and better performance across every project.

Post by: mur tokohasil.com