In today’s fast-paced lifestyle, consumers are more conscious about their health, diet, and food quality than ever before. One of the rising trends across India and worldwide is the consumption of pure, chemical-free oils extracted using a Cold Press Oil Machine. Unlike conventional expellers, which use high heat and solvents, cold press technology gently squeezes oilseeds and nuts at low temperatures, preserving natural flavor, nutrients, and aroma.

In this article, we will explore the benefits, applications, and latest innovations in cold press oil machines, along with practical buying tips and industry trends to help businesses, farmers, and individuals make informed choices.

What is a Cold Press Oil Machine?

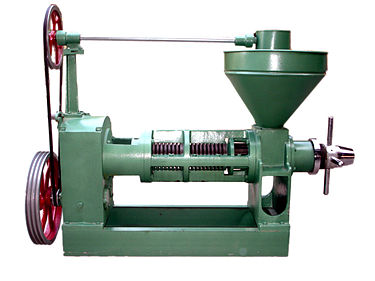

A Cold Press Oil Machine is a mechanical device that extracts oil from seeds, nuts, or fruits using hydraulic or screw-based pressing without applying excessive heat. The temperature is usually maintained below 50°C to protect vitamins, antioxidants, and natural flavors. Oils extracted this way are often referred to as virgin or wood-pressed oils and are considered healthier compared to refined or hot-pressed alternatives.

Common seeds processed in cold press machines include:

- Mustard

- Groundnut (peanut)

- Sesame

- Sunflower

- Coconut

- Flaxseed

- Almond

- Soybean

Why Cold Press Oils Are Popular in 2025?

With rising health awareness and demand for organic products, cold-pressed oils are making their way into households, restaurants, Ayurvedic clinics, and even export markets. The key drivers include:

- Health Benefits

Cold press oils retain essential fatty acids, Vitamin E, and natural antioxidants that promote heart health, skin glow, and improved digestion. - Chemical-Free Production

No external solvents or chemicals are used, making oils safe for daily consumption. - Authentic Taste & Aroma

The oil maintains the nutty, earthy, or fruity aroma of the original seed, which refined oils often lose. - Market Demand

Consumers are ready to pay a premium for cold press oil, making it a profitable business opportunity for entrepreneurs.

Advantages of a Cold Press Oil Machine

If you are planning to invest in a Cold Press Oil Machine, here are some compelling advantages:

- Nutrient Preservation: Minimal heat means oils are packed with vitamins and minerals.

- High-Quality Output: Suitable for premium packaging under organic or health-focused brands.

- Eco-Friendly Operation: Many machines consume less energy and create reusable by-products like oil cake.

- Versatility: Can process multiple types of seeds with one machine.

- Scalability: Available in domestic, semi-commercial, and industrial capacities.

Latest Innovations in Cold Press Oil Machines

The technology behind cold press oil machines has advanced rapidly. Here are the latest 2025 updates:

- Digital Control Panels

Touchscreen interfaces now allow operators to adjust temperature, pressure, and seed type for optimized yields. - Compact Domestic Models

Sleek kitchen-friendly machines for home use are trending, giving families the option to produce fresh oil daily. - Hybrid Screw & Hydraulic Technology

New machines combine screw pressing with hydraulic assistance to maximize extraction while retaining oil quality. - Smart Energy Management

Energy-efficient motors and AI-based monitoring systems reduce power consumption by up to 20%. - Food-Grade Stainless Steel Build

To ensure hygiene and durability, manufacturers are focusing on rust-free, easy-to-clean steel machines.

Types of Cold Press Oil Machines

Choosing the right type of cold press oil machine depends on your requirements:

1. Domestic Cold Press Machines

- Small, portable units for home kitchens.

- Process 2–5 kg of seeds per hour.

- Ideal for families seeking daily fresh oil.

2. Semi-Commercial Cold Press Machines

- Medium capacity, 10–20 kg per hour.

- Perfect for small businesses, restaurants, or local oil shops.

3. Industrial Cold Press Machines

- Heavy-duty machines capable of 50–200+ kg per hour.

- Suitable for large-scale edible oil businesses, cooperatives, and export units.

How to Choose the Right Cold Press Oil Machine?

When investing in a Cold Press Oil Machine, consider these factors:

- Capacity Needs: Domestic vs. commercial usage.

- Seed Compatibility: Ensure the machine supports multiple oilseeds.

- Build Quality: Look for stainless steel and durable components.

- Power Consumption: Energy efficiency reduces operational costs.

- Maintenance & Service: Check for local availability of spare parts and technical support.

- Warranty & Brand Reputation: Reliable after-sales support is critical for long-term use.

Cold Press Oil Business in India: A Golden Opportunity

India’s edible oil consumption is rising at a rapid pace, and health-conscious buyers are driving demand for cold pressed oils. Starting a business with a cold press oil machine can be highly profitable, especially in regions known for oilseed cultivation:

- Gujarat & Rajasthan: Groundnut and mustard oil

- Tamil Nadu & Kerala: Coconut oil

- Madhya Pradesh: Soybean and sunflower oil

- Uttar Pradesh & Punjab: Mustard oil

Small entrepreneurs and farmer groups (FPOs) can start local oil brands targeting kirana stores, supermarkets, organic shops, and online marketplaces like Amazon and Flipkart.

Benefits of By-Products: Oil Cake Utilization

When oil is extracted using a cold press oil machine, the leftover by-product—called oil cake—can be repurposed for:

- Cattle Feed (mustard, groundnut, soybean cake)

- Organic Fertilizer (sesame, neem cake)

- Industrial Applications like soap making or biofuel

This ensures zero waste production and additional income streams.

Maintenance Tips for a Cold Press Oil Machine

To keep your machine running efficiently:

- Regular Cleaning: Prevent clogging and residue buildup.

- Lubrication: Follow manufacturer’s guidelines for smooth operation.

- Check Electrical Systems: Ensure stable voltage supply and motor health.

- Spare Parts Inventory: Keep essential spares like filters, worms, and gears handy.

- Trained Operator: Ensure users understand machine handling and safety.

Common Challenges & Solutions

- Low Yield: Check seed quality and moisture levels.

- Overheating: Monitor machine load and ensure proper ventilation.

- Oil Cloudiness: Use proper filters and maintain seed cleanliness.

- Noise & Vibration: Regular servicing and alignment help reduce wear.

Future of Cold Press Oil Machines in India

By 2025, the Indian market for cold-pressed oils is expected to grow significantly, thanks to rising exports, government support for farmer cooperatives, and increasing online demand. With innovations in machine design, cold press oil machines will become more accessible, affordable, and efficient—empowering both households and businesses to produce healthy, chemical-free oils.

Conclusion

The Oil Machine is no longer a niche appliance—it’s a mainstream solution for healthier living and profitable businesses. Whether you’re a household looking for fresh, nutrient-rich oil or an entrepreneur planning to launch a sustainable oil brand, cold press technology offers the best blend of quality, safety, and profitability.

As consumer preferences continue to shift towards natural and chemical-free products, investing in a cold press oil machine in 2025 is one of the smartest decisions for both health and business growth.