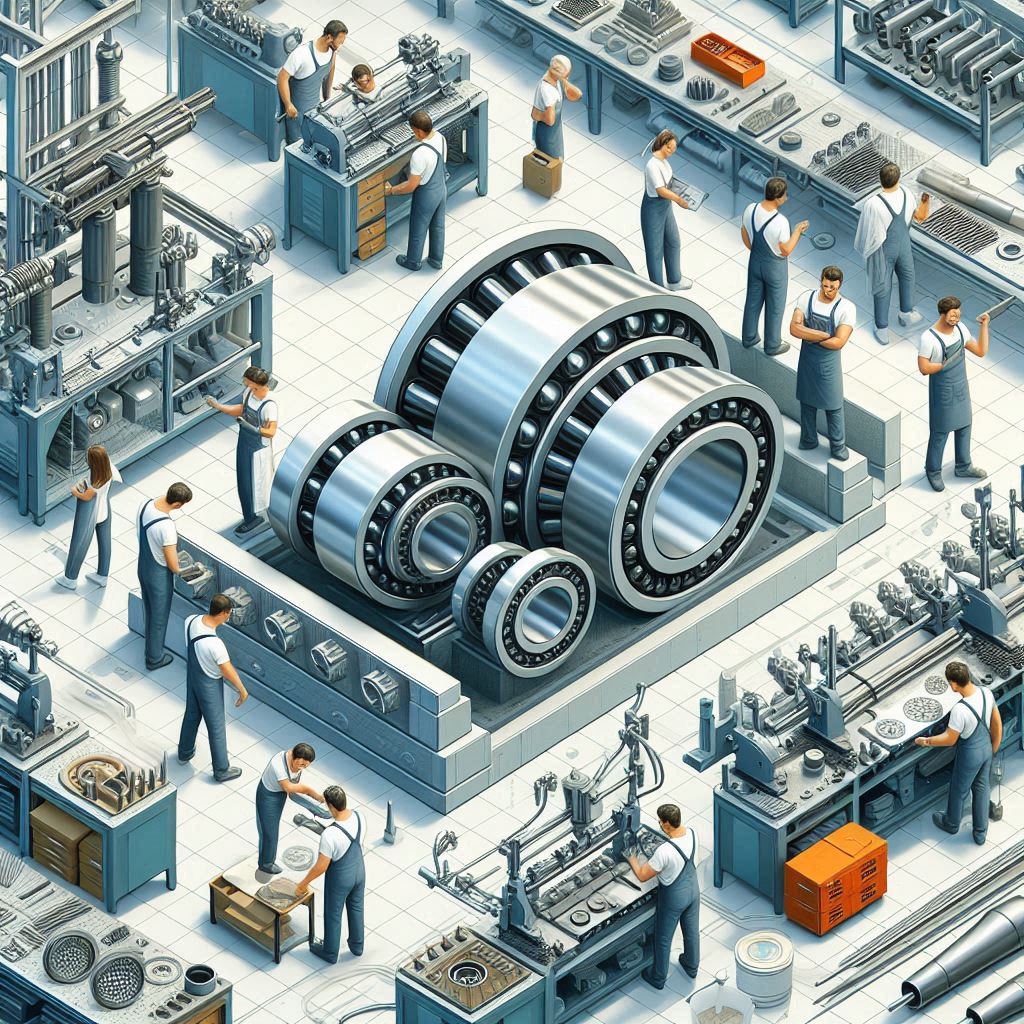

The manufacturing process behind high-quality pillow block bearings involves a combination of precise engineering, advanced materials, and stringent quality control to ensure durability and performance. It starts with selecting premium-grade steel or cast iron, which is forged and machined to create the bearing housing and internal components. Precision machining techniques, including CNC turning and grinding, are used to achieve tight tolerances and smooth surfaces essential for optimal bearing function. The bearing inserts undergo heat treatment to enhance hardness and wear resistance. After assembly, each pillow block bearing is rigorously tested for dimensional accuracy, load capacity, and rotational smoothness through non-destructive testing and performance evaluations. This meticulous process guarantees that the final product can withstand heavy loads and harsh operating conditions in various industrial applications.

Materials and Technologies Used by Leading Pillow Block Bearing Manufacturers

Leading pillow block bearing manufacturers use high-quality materials such as forged steel, cast iron, and sometimes stainless steel to ensure strength, durability, and resistance to wear and corrosion. These materials are carefully selected based on the application requirements, whether for heavy industrial machinery or more specialized environments like food processing or marine use. Manufacturers also incorporate advanced technologies such as CNC machining for precision shaping, heat treatment processes to enhance hardness and fatigue life, and surface coatings to improve corrosion resistance. Additionally, innovations like self-lubricating seals and advanced polymer cages are integrated to reduce maintenance needs and extend bearing lifespan. By combining superior materials with cutting-edge manufacturing technologies, pillow block bearing manufacturers deliver reliable, long-lasting solutions for demanding industrial applications and help in quicker pillow block bearing manufacture.

How Manufacturers Ensure Precision and Load Capacity in Pillow Block Bearings

Manufacturers ensure precision and load capacity in pillow block bearings through a combination of advanced design, material selection, and meticulous manufacturing processes. Using computer-aided design (CAD) and finite element analysis (FEA), engineers optimize the bearing geometry to evenly distribute loads and minimize stress concentrations. High-quality materials like forged steel and heat-treated alloys are chosen for their strength and fatigue resistance, enabling the bearings to withstand heavy radial and axial loads. Precision machining, including CNC grinding and turning, guarantees tight dimensional tolerances and smooth surface finishes, which reduce friction and wear. Rigorous quality control measures such as dimensional inspections, load testing, and non-destructive evaluations are conducted throughout production to ensure each bearing meets exact performance standards, providing reliable operation in demanding industrial environments.