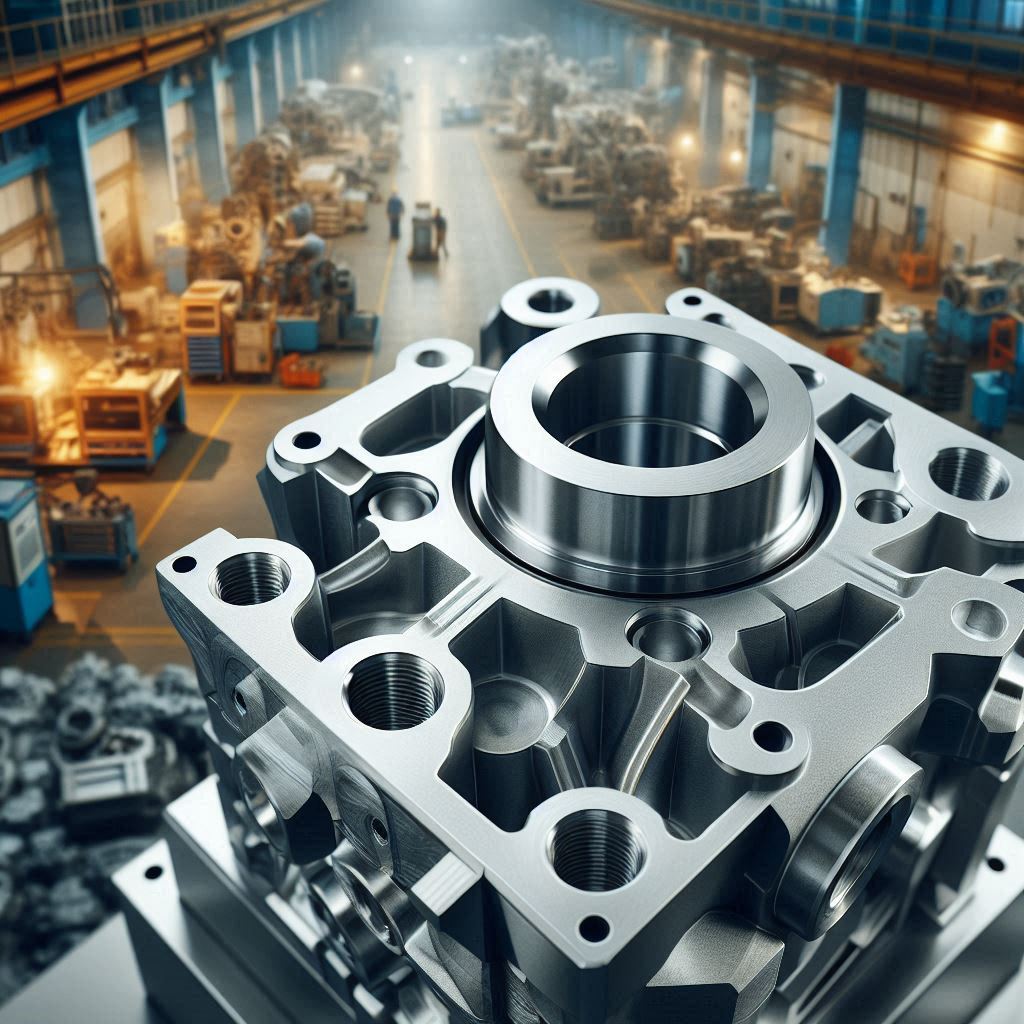

Precision investment casting, also known as lost-wax casting, is a highly accurate manufacturing process used to produce complex metal components with tight tolerances and excellent surface finishes. The process begins by creating a wax model of the desired part, which is then coated with ceramic materials to form a mold. Once the ceramic shell hardens, the wax is melted and drained out, leaving a cavity that is filled with molten metal to form the final component. This method is ideal for intricate designs and high-performance applications in industries such as aerospace, automotive, medical, and defense. Precision investment casting offers significant advantages, including reduced machining, material versatility, and the ability to produce near-net-shape parts with exceptional repeatability and detail.

Advantages of Precision Investment Casting in Modern Manufacturing

Precision investment casting offers numerous advantages in modern manufacturing, making it a preferred method for producing complex and high-performance components. One of its key benefits is the ability to create intricate geometries and fine details with exceptional dimensional accuracy, reducing the need for extensive post-processing or machining. This process supports a wide range of metals and alloys, including stainless steel, titanium, and superalloys, enabling its use across industries like aerospace, automotive, and medical devices. Additionally, precision investment casting delivers excellent surface finishes, minimizes material waste, and allows for consistent, repeatable production of parts with tight tolerances. These advantages contribute to lower production costs, improved component performance, and greater design flexibility—critical factors in the competitive landscape of modern manufacturing.

Materials Used in Precision Investment Casting and Their Benefits

Precision investment casting accommodates a wide variety of materials, each selected based on the performance requirements of the final application. Stainless steel is one of the most commonly used materials, valued for its corrosion resistance, strength, and versatility across industries like automotive and medical. Carbon steel offers high strength and cost-effectiveness, making it ideal for structural components. Aluminum alloys are chosen for their lightweight properties and excellent machinability, especially in aerospace and transportation. Superalloys such as Inconel and Hastelloy are used in high-temperature and corrosive environments, particularly in aerospace and chemical processing. Titanium is another premium material used for its outstanding strength-to-weight ratio and biocompatibility, making it ideal for aerospace and medical implants. The ability to work with such diverse materials makes precision investment casting a go-to solution for producing complex, high-performance parts across a broad spectrum of industries.